Koenig & Bauer introduces new modular exchange system

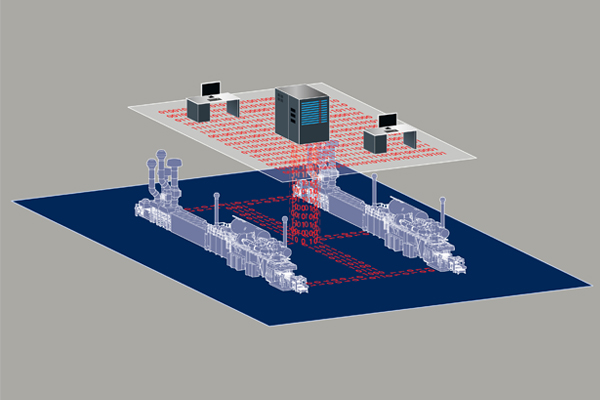

Printing press manufacturer, Koenig & Bauer MetalPrint has introduced its new modular exchange system (ModEX) which opens the coating line to an automated and smart way of coating metal sheets.

As the demands and ideas around digitalisation and automation are different from customer to customer, ModEX is designed in a completely modular way. This means the customer can decide which exact functionality they want to use, and can add additional modules at a later stage allowing the customer to grow and learn with the new possibilities ModEX has to offer.

The base – ModEX: Base module – opens all single machines, which are used in a coating line, to connect with the customer’s MES, PPS or MIS system. The interface uses the OPC-UA standard, an industry-wide common interface for machine connections. The coating line is equipped with an OPC-UA server, which is additionally secured with an integrated firewall securing the machine network from the shop floor or customer network.

Equipped with this technology, every machine is now able to provide machine messages, fault messages and actual values in real time to the customer system. With the base module, the communication between coating line and customer system is uni-directional.

Through the ModEX: Data exchange module (DEM), ModEX establishes a bi-directional communication to the customer system, allowing it to receive information about the next production job.

As well as the information from the base module (machine messages, fault messages, actual values) the data exchange module provides additional information back to the customer system such as sheets per pallet, overall sheets, gas consumption and oven temperatures recorded during production.

All information is automatically provided to the customer system at the end of each job, enabling the operator to focus on the production.

To support operators and accelerate processes, ModEX applies automation to coating lines, beginning with automatic start and stop of production depending on the sheets per job. If a double or triple stacker is installed, ModEX also changes the stacking box automatically as soon as the desired amount of sheet per pallet has been stacked.

ModEX will also set production parameters or produce documentation automatically, saving time for the operator. For example if job 1 requires temperatures of 200°C and job 2 requires 210°C, the ModEX will automatically start the rise of temperature in the heating zone as soon as the last sheet of Job 1 left the heating zone, in order to lose no time during the make ready process. Again, all without the interaction or delay of a manual action by the operator.

ModEX marks the start of Koenig & Bauer’s automation and digitalisation strategy. With more modules for ModEX currently in development and design, the range of functionalities and upgrades will extend.

ModEX is available for new coating and printing lines, with retrofits available on special request.